At BoltSafe, we provide advanced bolt load monitoring solutions that ensure accuracy, safety, and efficiency. Our services include real-time monitoring, customized integration, expert support, and training to help industries achieve reliable and optimized bolting operations.

BoltSafe delivers advanced bolt load monitoring solutions designed for accuracy, safety, and efficiency. From load sensors to digital monitoring systems and custom integrations, our products provide real-time insights and reliable performance across industries worldwide.

Our RS-232 and Analog Converter can connect a BoltSafe CMS load cell directly to any data acquisition system (DAQ), computer or PLC. The Analog Converter automatically scales the analog output from the attached sensor. The maximum bolt load from the sensor equals 100% of the analog output (5Vdc, 10Vdc or 20mA).

The BLE-node offers a very long battery life of approximately five years. This makes the BLE-node extremely useful for rotating or moving applications. With our free accompanying “BoltSafe Connect” software, you can change the log interval or download the stored data from all BLE-nodes within a range of 100 meters (free sight) in one action.

.png)

The BoltSafe bolt load cell is a specially designed load cell (load sensor) that monitors the actual bolt load in bolted joints. CMS stands for Continuous Monitoring System, which allows for continuous monitoring of the bolt load from one connection point. Several load sensors can be interconnected within a network.

The CMS-NC is the next step in the evolution of BoltSafe’s well-known CMS bolt load sensor. This sensor offers the possibility of disconnecting the cable from the CMS load cell. This is very useful in case of continuous monitoring where a permanent cable is not an option, when there’s a risk of damaging the permanent cable.

The BoltSafe handheld reader is a handheld instrument that reads and stores data from both the CMS (Continuous Monitoring System) and PMS (Periodic Monitoring System) BoltSafe load cells.

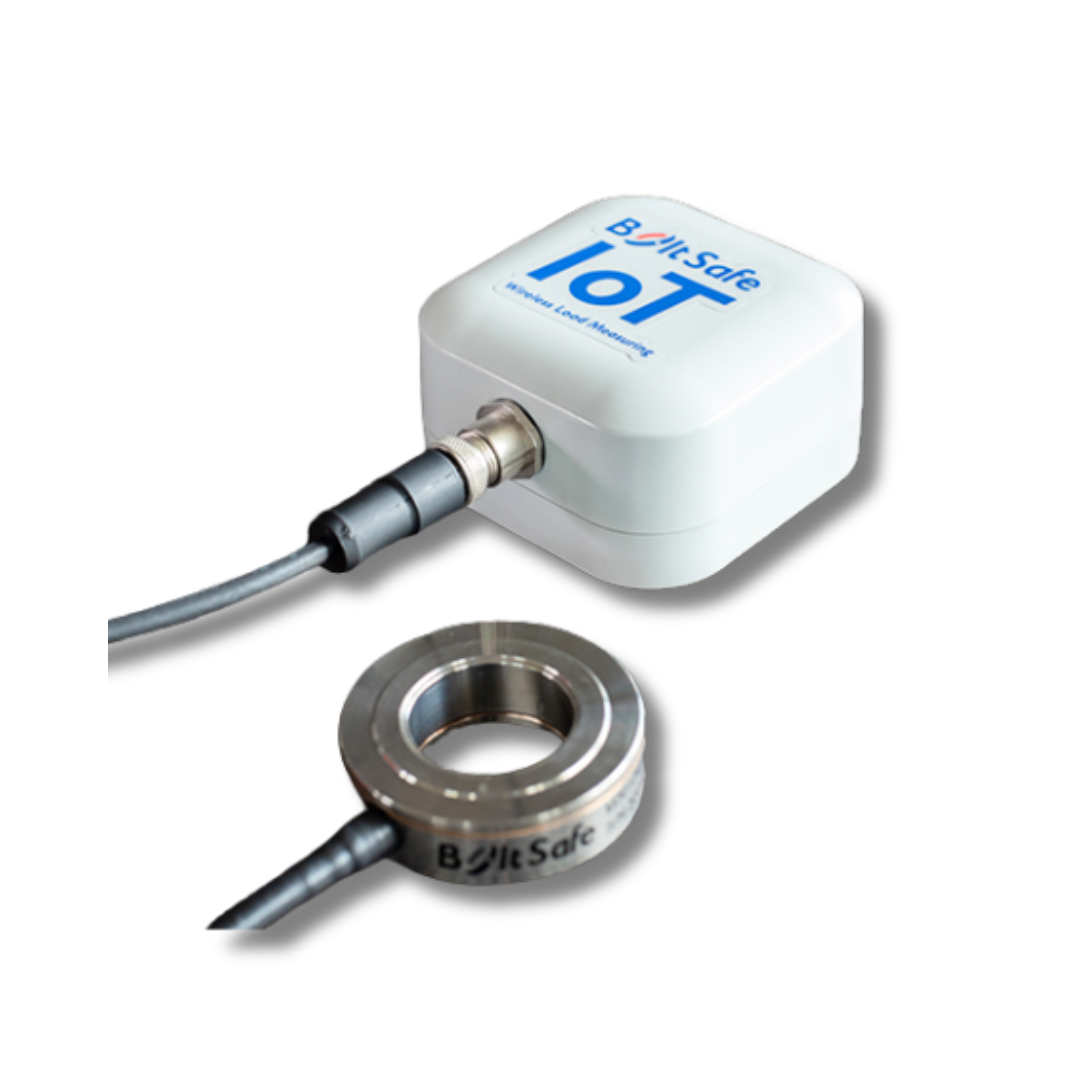

The IoT-node is our latest technology. It is able to connect one BoltSafe CMS sensor to The Things Stack, KPN LoRa network or any other (private) LoRaWAN network. IoT stands for Internet of Things. We use the LoRaWAN technology, which stands for Long Range Wide Area Network.

.png)

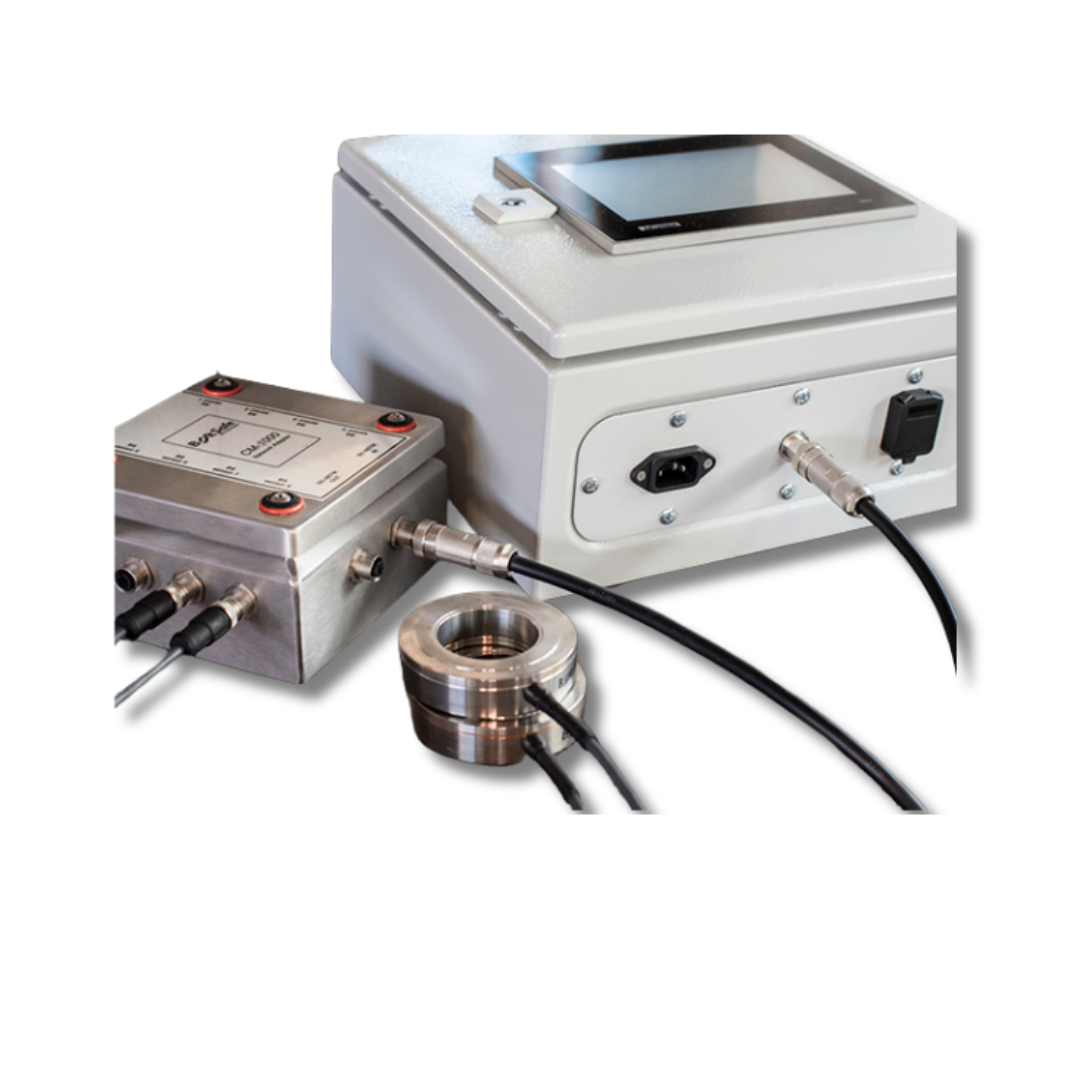

Our network with PDI-NT readout method consists of a PDI-NT (Power Data Interface New Technology) box and a CM-1000 box or a network of these boxes. Using these boxes, the bolt load from CMS sensors can be continuously visualized. The PDI-NT is a connection box that connects the BoltSafe sensor network.

The PDI-NT makes it possible to have a standalone BoltSafe system. When the system is configured, the software automatically assigns node numbers to each unit connected to the system. There is no need for any extra settings or coding during installation. The data is directly logged to the PDI-NT.

© 2026 Boltimizer Corporation. All rights reserved.